Products

Stampings

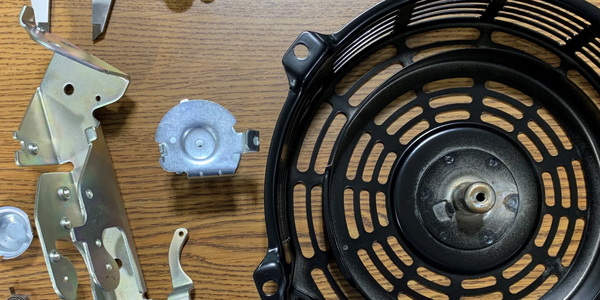

With metal stamping presses ranging in size from 75 to 500 tons we typically produce over 2 million stamped components each month. Materials we use include cold rolled, hot rolled, galvanized, galvanneal, aluminum, and stainless steel. We have our own tool room to ensure quality stampings with reliable processes.

Products we stamp vary from simple heat shields and brackets to components we use to create mechanical assemblies. We also offer powder coating and work with several companies to perform any additional operations such as plating and heat treatment of components before we perform final assembly, inspection, and packaging.

Recoil Starters

Starting USA has produced over 250 million engine recoil starters for customers throughout the world. We have recoil design capabilities locally at our Poplar Bluff, Missouri plant, as well as at the Starting Industrial home office in Japan.

In a typical year we will manufacture over 6 million recoil assemblies used on a variety of small engine applications ranging from consumer lawn mowers and hand held power tools to commercial lawn and garden and utility equipment.

We produce our own springs and stamped components for our recoils in house and source our plastic components from local and global suppliers in order to produce the patented design.

Mufflers and Thermostatically Controlled Choke Actuators

At Starting USA Corporation we typically manufacture 2 million mufflers a year using automated processes to assemble the mufflers from components we stamp and fabricate. Our use of automated equipment and our low overheads mean that we are competitive globally with our muffler manufacturing process.

In addition to mufflers, we also produce a patented thermostatically actuated choke system that is integrated into the muffler itself. We manufacture the components for this thermostat "in house" including the forming of the bimetallic spring.

Product Photo Gallery

Stamped shields

Manufacturing Highlights

Copyright © 2023 Starting USA Corporation - All Rights Reserved.

Powered by GoDaddy

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.